Quality control of NSP products

Contents

- Quality Data Sheets

- Samples of raw materials

- Microbiological testing

- Inspection of equipment cleanliness

- Anaerobic testing

- Organoleptich-identif

- Microscopy

- Thin Layer Chromatography (TLC)

- Infrared Spectroscopy (FTIR)

- High Performance Liquid Chromatography (HPLC)

- Foreign Body Test

- Ash Test

- Acid Solubility Test

- Checking for radioactivity

- Gas Chromatography (GC)

- Mass spectrometry (MS)

In the modern world, the environmental situation leaves much to be desired. And people are increasingly thinking about the naturalness of a particular product. Increasingly, he chooses organic food, cosmetics and other products. It is natural products, according to experts, that are able to support the human body in the face of a negative impact on it, an aggressive environment.

By following the production process of Natures Sunshine products, you will understand how safe our products are.

NSP specialists begin quality control at the stage of collecting suitable raw materials. These are all kinds of plants and herbs. Only those fees that have undergone in-depth studies of useful properties get into production. Each herb has a period of accumulation of beneficial properties. Therefore, all plants are collected strictly during the peak of their usefulness.

Modern technologies, combined with many years of experience, provide the most optimal balance of benefits and safety for the body. The vitamins and minerals contained in Natures Sunshine products will provide you with a boost of energy and a good mood.

We are responsible for the quality of Natures Sunshine products. This is not just our choice, but an obligation that the company's management assumes. The high quality of the original products is not a goal, but rather a standard daily procedure. NSP has become a leader among manufacturers of health products - the so-called dietary supplements. Natures Sunshine dietary supplements are absolutely safe.

All plants are sent to production immediately after harvest, bypassing the storage stage. Here they are checked again, subjected to a mandatory test for purity and the absence of foreign fractions, impurities and inclusions. They also check the effectiveness of all medicinal components and the strength of their effect on the body.

The most important thing to know about the company's attitude to product quality: the company produces only high-quality products according to strict standards. For this reason, poor quality raw materials were returned to suppliers and good quality raw materials were expected for the production of the following products (i.e. products were not produced until raw materials that met quality standards were received):

- Pow-pow - 2018

- Perfect eye - 2000.

Watch a replay of Nature's Sunshine Products VP Quality, Linda Hammons

The main production complex is located in Utah, USA. Production facilities are located on an area of more than 9 thousand square meters.

A special research complex operates here, which develops medicinal formulas that are unique in their composition. Natures Sunshine dietary supplements are developed by specialists of the highest level of training. They go through many years of practice before getting into production. The formulas they create are not only of high quality and meet all modern requirements, but also have no analogues in the world.

Production itself begins with the stage of receiving raw materials - 7.5 thousand special containers store the original product. For the correct and most effective storage, the most modern method is used - “dry freezing”. This method involves the use of extremely low temperatures. At the same time, all the beneficial properties of medicinal herbs and plants are preserved.

In production, with the use of medicinal herbs, fillers are not used. Natures Sunshine uses processing aids to produce capsules and tablets. In this case, the most commonly used: fiber, calcium or magnesium stearate, silicon dioxide. All these are components of natural, natural origin.

More than half of all Natures Sunshine products are capsules. Approximately 60% of production. Approximately 6,000,000 capsules roll off the assembly line per day. As for tablets, their production is more modest - only 95,000 tablets per day. About 22,000 bottles and vials are packed in boxes in the shops where liquid additives and other non-flowing and tablet additives are produced.

Natures Sunshine has equipped its production facility with modern million dollar equipment. It, together with other measures, ensures the quality of the finished product. The company has earned itself an unsurpassed reputation in the markets of different countries. This allows the company to remain the market leader in the production and sale of dietary supplements for more than 40 years.

The company itself is engaged in research in its own pharmaceutical laboratory. High-class specialists work here. They are engaged in carrying out all kinds of tests and develop new products. For laboratory research, as well as for production, the most modern equipment is used.

The group of scientists includes world luminaries biochemists. They specialize in dietary and healthy nutrition as well as the latest pharmaceutical technologies. Their efforts have created a line of products that is unparalleled in the variety of forms and properties of drugs. Most drugs are patented, because. they were developed in the Natures Sunshine laboratory. And that is why in most cases the packaging of our products says "patented". The same instructions are in all modern reference books of medicinal mixtures.

Testing procedure

Natures Sunshine follows a policy of maximum openness, therefore it does not hide any information about the quality of its products and the progress of production. After all, NSP’s motto is “Quality, Service, Honesty.” Only high-quality raw materials are used in production, since without them, the company’s specialists are sure, it is impossible to produce a high-quality product.

Not just one batch is subjected to the strictest inspection in production, but all batches. Without exception. Before delivering the finished product to sales points, we must be sure that all stages of verification have been completed correctly and without violations. Our specialists continue to test products at all stages. Our team of specialists conducts more than 300 tests daily, tracking the path of each shipment of goods. The total number of tests to which products are subjected is more than 600.

Samples of raw materials

All samples of raw materials are tested for compliance with the entire batch. All tests are carried out in strictly isolated rooms to avoid mixing of samples or contamination with harmful substances. Raw materials, the quality of which has been confirmed, go further to the laboratory, where more in-depth studies are being carried out.

Quality Passport

To obtain the so-called "quality passport", a product must pass a series of tests. And then a list of them with a description of the process.

Microbiological examination

Bactometer is a special device that is used to determine the purity of a product, confirm its quality and non-infection. Alternating special electronic signals passing through the sample indicate an increase in the number of pathogenic flora. In the case of increased electrical conductivity, this is a signal of an excessive number of microorganisms. Both the primary raw materials and the finished product are subjected to such a microbiological study. This is done to ensure that all manufactured products meet company standards.

The most modern equipment is used in production to check the quality of the source material. That is why NSP is the undoubted leader in the market. We are the first company to apply the achievements of modern technology for the production of dietary supplements.

The quality control department, only in the last few years of work, has "deployed" from production several batches of raw materials that have not passed the infection test. Timely detection of E. coli and Salmonella helped prevent serious infection. However, as experts note, not all manufacturers are ready to conduct costly additional studies and checks at their own expense. In most cases, raw materials not accepted by NSP are sent to other plants.

Equipment Cleanliness

Natures Sunshine uses two state of the art methods to deep clean work equipment. To check, in the first case, samples are taken from the surface of the equipment. They are sent for a microbiological test. Samples are repeatedly diluted, the total number of microorganisms is counted in them.

In the second case, the energy-consuming properties of cells are changed using a unique device. This device is called a Bioluminometer. It allows you to find impurities and sediments, as well as any contamination on the surface of the equipment. The essence of the method is simple - measuring light emission. As a rule, a combination of these two methods is used in production. So specialists can give a 100% guarantee of cleaning and compliance with all sanitation standards.

Anaerobic testing

Testing for Acidophilus and Bifidobacterium is one of the most complex and time-consuming tests. The Natures Sunshine company is the first and perhaps the only one to carry out such testing in the production of dietary supplements. The fact is that Acidophilus and Bifidobacterium belong to a group of bacteria. They have a positive effect on the human body in general and on intestinal functions in particular.

These bacteria can reproduce without oxygen, that is, they are anaerobic. A high content of Acidophilus and Bifidobacterium is found in such products of the line as Bifidophilus Chewable for Kids and Bifidophilus Flora Force. One capsule of the drug contains several million of these bacteria. The tests use not only specially designed equipment. But also analytical programs developed in production. They find and accurately count all anaerobic bacteria.

The standard test takes place in six stages. It takes up to three days. However, our specialists have created a technologically more complex procedure to speed up the testing process. As a result, it takes only 24 hours to get results.

Testing of medicinal herbs for product purity also takes place in several stages.

Organoleptic identification

This is the first step in classifying all herbs. Samples of raw materials must pass the strictest quality control. This is, among other things, a test to determine the main properties of herbs: taste, smell, color, appearance. The plants are not manufactured in a factory, they are natural and grow in nature, so minor differences in characteristics are allowed. Depending on the season, weather, or simply over time, properties may change. Nevertheless, under any circumstances they must comply with the classification.

Microscopic examination

Using a simple microscopic examination, you can determine the composition of the sample, that is, the ratio of particles. For example, microparticles of roots, leaves, bark, and fruits can be recognized in grass samples. Using this method, you can easily determine what is more in the sample. Are there any impurities or foreign bodies, such as debris or insect particles? Testing is divided into preparing a snapshot and testing itself. This method allows you to identify and classify a sample according to a number of undoubted characteristics. Most often, the majority of contaminants are determined at the first stage.

Thin layer chromatography (TLC)

TLC is an analysis method that helps recognize possible deviations in the quality of a raw material or product. A specially developed technique allows you to separate different plant particles from each other. The resulting mixture is transferred drop by drop to the plate and thus the concentration of the extract is calculated.

A team of specialists monitors the quality of the substance. They focus on the color of the concentrate. The mixture is checked for discoloration. For this purpose, a specialized spray developed in the company’s laboratory is used. Ultraviolet light is also used.

This test allows you to obtain photographs of samples for comparison with the standard or with samples from previous tests.

Another method used in laboratories is infrared spectrography. It is combined with TLC for greater accuracy of research. Spectography allows you to verify the quality composition of plants, in the presence of all components that are necessary in production. It also establishes the correct ratio of components. And with the help of these two tests you can compare finished NSP products with products from other brands. This is how the purity of active substances is usually determined.

TLC and FTIR help determine:

- whether there are radionuclides in the samples;

- what is the degree of contamination. Moreover, the accuracy of such a study reaches parts per billion;;

- what is the percentage of active substances;;

- are there active substances, minerals and trace elements in the samples (there are about 40 in total) and what is the degree their activity;

- are there any volatile essential oils in the samples and what is their quantity.

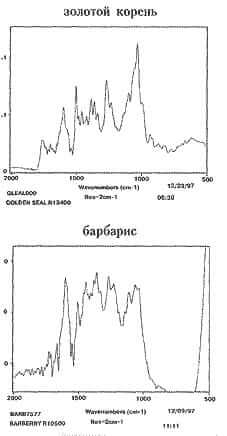

Infrared Spectroscopy (FTIR)

In-Entities FTIR is an identity detector. With its help determine the purity of the sample and its authenticity. All samples differ in the permeability of infrared rays. Depending on the patency, the classification is confirmed. The sample absorbs the energy of the infrared beam, and as a result, a graph is drawn up and a spectral analysis is obtained.

In terms of composition, FTIR is somewhat reminiscent of Michelson. The state of the plant is evaluated exactly according to the graph, since plants cannot give the same picture on the graph. By the way, this is a very effective way to identify forgery. This is the final test that allows you to dot all the "i". Healing plants, like any other, differ in color, smell, taste. This means that the spectral pattern should also be different. Analogues can be very similar to the original. However, analogues will cost less. Sometimes the difference in price can be 25 times.

It is in order to avoid forgery (intentional or accidental) that this test is carried out. Cheaper herbs are often brought into production under the guise of more expensive ones. They, of course, will differ in their healing properties. But to determine this by eye, of course, is impossible. Most often, the Golden Root is subjected to forgery. This is a very expensive raw material. It is in great demand. Therefore, often suppliers simply mix it with other crops to get more material, and therefore more profit. However, FTIR easily detects fraud by determining the exact chemical composition of the sample.

Natures Sunshine has been using this technology for a long time. Therefore, our specialists can easily identify any deviations from the norm. This means that the finished raw material always corresponds to a high level of efficiency and quality.

High Performance Liquid Chromatography (HPLC)

HPLC is state of the art equipment, highly sensitive and automated. With its help, the ingredients of the formulated solutions are identified and analyzed. The main thing for which this equipment is used is the definition and sorting of the components of the drug. It is on this equipment that all finished products of Natures Sunshine are tested. Specialists determine the quantitative composition of active and excipients, which guarantees the quality of the dietary supplements produced.

HPLC is also used in the first stage of raw material processing. With its help, the raw materials are checked for purity and strength of active substances. If the research results do not meet the established standards, the raw materials are not allowed for production.

Finished products are checked for compliance with the standards without fail.

Foreign Body Test

Ash residue test

Ash residues - microparticles of herbs are set on fire during this test. To do this, use a special microwave oven. The heating temperature here reaches 700 degrees. Heating goes on for an hour. Organic matter burns. The ash, if it remains, is the impurities or foreign bodies. It can be inorganic fertilizers, dust, foreign minerals. The ashes must be weighed. This is then taken into account in the final results.

Each culture has its own set of properties of the mineral composition and ash composition. If the composition of the ash changes during the test, then the raw material is of poor quality, or foreign bodies have got into it. This is a fairly common problem faced by manufacturers of dietary supplements. When collecting plants with roots, soil particles, etc., most often fall into the samples. Upon detection of a severe degree of contamination of raw materials, Natures Sunshine refuses a particular batch or (in case of repetition) from the supplier's services at all.

Acid solubility test

Ash obtained from the previous test is mixed with hydrochlorinated acid. The mixture is then ignited again. In this case, any ash will be considered oxidized insoluble (AIA). A high level of AIA is considered proof of the content of metal particles in the raw material. It can also be salts of heavy metals, which are very dangerous for humans. Such samples can never meet the standard.

Checking for radioactivity

In modern production, all samples of raw materials imported from Europe should be checked for radioactivity. Most often, these samples turn out to be with a high level of radiation. This is due to the Chernobyl accident. The gamma test is an integral part of the test. A special counter determines the level of radiation and the degree of pollution.

Gas chromatography (GS) or Mass spectrometry (MS)

GS is a specific study that breaks down the original components. Part of the dissolved substance is placed in a special unit. It turns into a gas at high temperature. As long as there is gas in the apparatus, a special program determines the constituent elements. Strictly defined particles settle in a special block. It's called MS. This compartment defines the smallest elements of the particles. The latest equipment installed in the Natures Sunshine laboratory detects harmful trace elements and impurities. For example, you can define the use of pesticides.

Two tests evaluate the main components of a wide variety of essential oils extracted from plants. Depending on the type of oil or the country of origin of the feedstock, the indicators will be different. With this test, you can also determine the forgery.

For example, Oregano oils from Morocco and Turkey have a fundamentally different qualitative composition. They also differ in price, which often causes forgery.

Additional Research

Plasma spectrometry (ICP - MS)

Plasma spectrometry (ICP - MS), ICP - MS is another apparatus for mixing and formulation of drug combinations. In this case, finished products are examined. The material to be tested is immersed in acid and then ignited. Depending on the color in which the substance is painted, the composition of the samples is determined. All elements have their own set staining colors.

Dissolution Test

Natures Sunshine Laboratories have state-of-the-art equipment that can mimic the process of digestion. This is a mandatory line of tests for finished products. With its help, you can determine how the human body will react to a particular component of the drug. Research helps to compile a set of additional supplements that will help speed up the digestion process and the absorption of drugs. In particular, our most famous dietary supplements were tested on this equipment - Vitamin C, Omega 3, Prostate Formula, Stomach Comfort and others.

The test reproduces intestinal motility, temperature regime and other features of the digestion process. The company gets a clear picture of quality control, as if the capsule or other product was in the human gastrointestinal tract.

The production is equipped with the most highly sensitive equipment that analyzes the tests performed. These are HPLC and UV Vis. They show the speed and conditions of assimilation of drugs.

Cleavage test

Similar to digestibility test. Pharmaceutical standards in the United States require manufacturing companies to conduct this test. Ready capsules and tablets are placed in heated, up to 37 degrees, water. All movements of the specific apparatus imitate the process of "travel" of the capsule in the body. In this case, the time for the splitting of drugs is strictly fixed. According to NSP standards, this process should not take more than half an hour.

Inspection of finished products

NSP has made it a rule that each package of finished products is inspected. Not a single batch comes to the consumer without a stamp on the passed tests and checks.

Most Important Tests and Experiences

Natures Sunshine products are tested through various tests and experiments from start to finish. Quality is checked at all levels, from raw materials to finished goods. You can find a complete list of the main experiments and tests that are carried out in the company's laboratory:

- Ash residue test;

- Acid solubility test; Essential Oil Determination;

- Gas Chromatography/Mass Spectrometry (GC/MS);

- Thin Layer Chromatography (HPLC);

- Infrared Spectroscopy;

- Moisture content test;

- Organoleptic identification;

- Ph value determination;

- Salmonella test;

- Thin layer chromatography (TLC);

- Solution-free acid test;

- Bacteriological test;

- E. coli test;

- the presence of foreign impurities of organic / inorganic origin;

- Test for the presence of heavy metals;

- Plasma spectrometry (ICP-MS);

- Microscopic analysis;

- Mold and yeast test;

- Particle size determination;

- Substance activity test;

- Tablet solubility test;

- Determination of the viscosity index;

- General bacteriological examination;

- Finished product testing;

NSP quality standards are accepted worldwide as a benchmark. For example, ISO (9000/2000) was created on their basis in 2001. And this is one of the few examples of international quality control standards for manufactured pharmaceutical products.

Each year, NSP spends about $2,500,000 million just to improve the quality control system that loops the entire process from raw materials to the final product. To date, the quality of raw materials and production technologies of Natures Sunshine products is ahead of the world level. And the advance of individual technologies is from 5 to 10 years!

NSP products meet all quality standards, including FDA and TGA, documents confirming this can be found at page certificate.

You also have the option to download the 4 Steps to Proven Quality flyer in PDF, which focuses on product quality and research. Download from this link.

Clinical trials have also been conducted in other countries. This information is provided in the article "Experience in the clinical use of dietary supplements Natures Sunshine Products" NN 1, 2, 2005 (A.F. Novikov, Department of Nutrition and Preventive Medicine, International University of Peoples' Friendship, Moscow). And in the materials of the IV international conference "BAA and problems of optimizing the nutrition of the population" 2002, Sochi.

Product quality improves and increases with each new experience or test. For the company, high product quality is the main factor that has propelled Natures Sunshine products to the top of the industry.

Company Lab

To start with, Nature's Sunshine Products Inc. not one lab, but SIX labs.

Innovation is at the heart of Nature's Sunshine Products. The gifted scientists of the Research and Development Lab and the Methods Lab are always on the lookout for the next big breakthrough. They strive to always find ways to fine-tune the formulas of our products to get great results. And always looking for more effective ways to enhance wellness and transform lives.

Over the past forty-two years, the company has studied and determined the optimal formulations for tens of thousands of natural ingredients. She is fully and every year more committed to developing and learning in this direction.

Science means criticism too. A full staff of Doctors of Science in Quality Assurance are focused on testing every natural ingredient in the company's products in the Microbiology, Vitamins, Minerals and Herbs laboratories.

That's why the company confidently guarantees the purity and potency of every product that bears the Nature's name Sunshine Products.